News

13

2022

-

10

How much do you know about grooved piping connection technology

Author:

Tuwei

Page views:

Pipes are used in construction projects and water supply and drainage projects, steel pipes are often connected. The traditional connection methods are mainly include welded piping connection, flanged piping connection and threaded piping connection, but they are troublesome, labor-intensive, difficult to ensure quality, and sometimes they will damage the steel pipe, affecting the project quality. In recent years, steel pipe grooved connection technology has been favored in pipeline construction.

What is grooved piping connection?

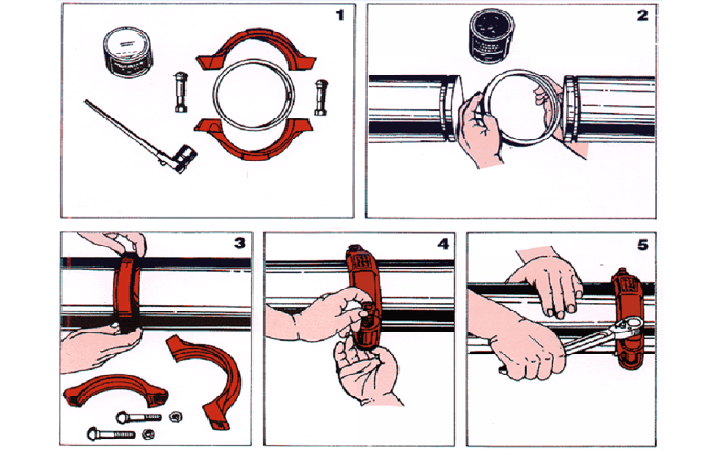

The grooved piping connection is mainly composed of grooved pipes, coupling, rubber sealing rings and bolts. During pipe installation, it is necessary to make required grooves with roll grooving machines, then place the rubber sealing rings on the outside of the connected pipes and match them with the grooves, then put a coupling on the outside of the rubber ring, and fasten it with bolts.

What are the advantages of grooved piping connection

1.Easy and quick installation: the grooved piping connection requests grooving only for on-site installation, which greatly simplifies the working procedure, and twice faster than flanged piping connection. In addition, the grooved connection pipeline is easy to install, and it can be done within a few minutes, which can effectively improve work efficiency.

2.The original properties of the pipe are not affected: the grooved piping connection only uses a roll grooving machine to make a groove on pipe which will not damage the internal structure of the pipe.

3. Convenient maintenance: the grooved piping connection can be maintained easily with limited space. When the pipeline needs to be repaired or replaced, it only needs to loosen coupling to repair a section of pipeline without damaging the surrounding walls, which greatly reduces maintenance time and maintenance cost.

What are the process of piping connection with grooved fittings?

Grooved pipeline installation should be in accordance with the principle of installing large-diameter pipes, main pipes and standpipes first, and installing small-diameter pipes and branch pipes later. Using BIM technology, firstly layout to determine the direction and position of the pipeline, clarify the location of mechanical accessories and grooved accessories, then preparation →grooving →hole cutting →installation (mechanical tee and cross first, pipe later) →pipe pressure test

The operation points of piping grooved connection

1.Pipe grooving: Cut the pipe to the required length with Tuwei brand TWQ-IIIA pipe cutting machine and the pipe should be square cut without burrs, then place the pipe on the Tuwei brand TWG-IIA roll grooving machine and pipe support, adjust the height of pipe support to horizontal or 1 degree lower. set groove depth then start grooving, stop machine when groove depth is in place. Release the relief valve, remove the pipe, and measure the groove depth with a PI ruler to confirm whether it meets the groove spec.

2. hole cutting: When installing the mechanical tee and cross, firstly use Tuwei brand TWK-IIIA hole cutting machine to make holes. Notice to select the corresponding hole saw according to the requested hole diameter, put the machine on the pipe horizontally then fix it with chain, start the machine, slowly rotate the handle to make holes. Add coolant to the saw during operation to extend its service life .

3.Grooved fittings installation: According to the relevant technical requirements, at first, groove the pipe and remove the burrs if needed, to ensure the pipe end is flat and smooth, then place the rubber sealing rings on the outside of the connected pipes and match them with the grooves, then put a coupling on the outside of the rubber ring, and fasten it with bolts .

The grooved piping connection is simple in operation, reliable in quality, convenient in maintenance, and small damage to the material of the pipeline itself. It is believed that it will play a great role in the future pipeline connection. Victualic-Tuwei company as been deeply involved in the pipe tools industry. Roll grooving machines, pipe cutting machines, hole cutting machines, pipe threading machines and other products developed by Victaulic-Tuwei receive a good reputation because of its high quality and good performance. If you have any pipe tools needs or anything doubts, welcome to contact us at any time.

[keywords]

the advantages of grooved piping connection,pipe grooving,hole cutting,grooved fittings installation

NOTICIAS RELACIONADAS

HOT PRODUCTS